EPDM rubber gaskets, commonly known for their exceptional durability and versatile applications, are vital components in various industries due to their unique properties and capabilities. EPDM stands for Ethylene Propylene Diene Monomer, a synthetic rubber material renowned for its outstanding resistance to environmental factors such as heat, ozone, weathering, and UV exposure. This makes EPDM rubber gaskets highly suitable for a wide range of demanding sealing applications across industries including automotive, construction, HVAC (Heating, Ventilation, and Air Conditioning), aerospace, marine, and more.

One of the most notable features of EPDM rubber gaskets is their exceptional weatherability. They can withstand extreme temperatures ranging from -50°C to 150°C (-58°F to 302°F), making them ideal for both indoor and outdoor applications where exposure to harsh environmental conditions is common. Whether it’s enduring intense sunlight, heavy rainfall, or freezing temperatures, EPDM rubber gaskets maintain their integrity and sealing performance over prolonged periods, ensuring reliable operation and extended service life.

Furthermore, EPDM rubber gaskets exhibit excellent resistance to ozone and oxidation, which are common causes of rubber degradation over time. This resistance translates into superior longevity and reliability, making EPDM gaskets a preferred choice for sealing applications in environments where exposure to ozone-rich atmospheres or oxidative agents is unavoidable.

In addition to their exceptional weatherability and resistance to environmental factors, EPDM rubber gaskets also boast excellent chemical resistance. They are highly resistant to a wide range of chemicals including acids, alkalis, solvents, and various industrial fluids, ensuring reliable sealing performance even in chemically aggressive environments. This chemical resistance further enhances the versatility and applicability of EPDM rubber gaskets across diverse industries where exposure to different chemicals is prevalent.

EPDM rubber gaskets are also known for their flexibility and elasticity, allowing them to conform to irregular surfaces and maintain a tight seal under varying conditions. This flexibility ensures proper sealing even in applications with complex geometries or dynamic movements, minimizing the risk of leaks and ensuring optimal performance.

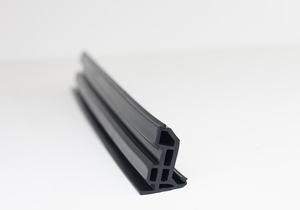

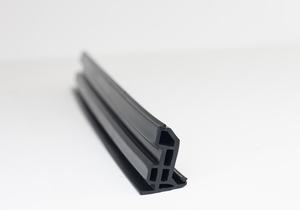

Moreover, EPDM rubber gaskets are available in a wide range of shapes, sizes, and thicknesses to suit specific application requirements. Whether it’s simple static seals, dynamic seals subjected to movement, or intricate gasket profiles for specialized applications, EPDM rubber gaskets can be customized to meet the unique needs of different industries and applications.

Overall, EPDM rubber seals offer a combination of superior weatherability, chemical resistance, flexibility, and durability, making them indispensable components in various sealing applications across industries. Whether it’s sealing automotive components, HVAC systems, pipelines, or industrial machinery, EPDM gaskets deliver reliable performance, longevity, and cost-effectiveness, ensuring efficient operation and protection against environmental factors for critical equipment and infrastructure.