Infrastructure gaskets are essential components used in various construction and civil engineering applications to provide a secure seal between different structural elements, pipes, and fittings. These gaskets play a crucial role in maintaining the integrity and functionality of infrastructure systems, including water and wastewater networks, transportation systems, and utilities. A comprehensive description of infrastructure gaskets encompasses their types, materials, applications, installation methods, and benefits.

1. Types of Infrastructure Gaskets:

Infrastructure gaskets are available in various types tailored to specific applications and sealing requirements:

- Flange Gaskets: Used in flanged connections to seal the interface between two mating flanges. Flange gaskets come in different configurations, including ring gaskets, full-face gaskets, and spiral wound gaskets, to accommodate different flange designs and pressure ratings.

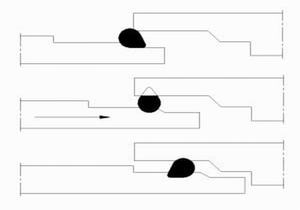

- Pipe Gaskets: Installed between pipe joints to create a leak-tight seal and prevent fluid or gas leakage. Pipe gaskets may be flat, beveled, or molded to match the shape of the pipe end and the mating surface.

- Manhole and Hatch Gaskets: Sealing gaskets used in manholes, access hatches, and inspection chambers to prevent water ingress, odor leakage, and the entry of debris or contaminants. Manhole and hatch gaskets are designed to withstand varying pressures and environmental conditions.

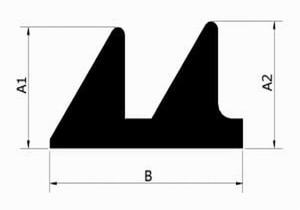

- Expansion Joint Gaskets: Employed in expansion joints to accommodate movement, vibration, and thermal expansion in infrastructure systems such as bridges, pipelines, and buildings. Expansion joint gaskets may be made of flexible elastomeric materials or metal with corrugated designs.

- Rubber Seals: Elastomeric seals made of materials such as neoprene, EPDM, or nitrile rubber, providing flexibility, compression, and resilience to maintain a watertight seal in dynamic environments.

2. Materials:

Infrastructure gaskets are constructed from materials selected for their durability, chemical resistance, temperature tolerance, and sealing properties:

- Elastomers: Common elastomeric materials include neoprene, EPDM (ethylene propylene diene monomer), nitrile rubber (NBR), silicone rubber, and fluorocarbon rubber (Viton). Elastomeric gaskets offer excellent resilience, compression set resistance, and sealing performance over a wide range of temperatures and pressures.

- Non-metallic Materials: Materials such as compressed non-asbestos fiber, PTFE (polytetrafluoroethylene), and graphite are used for their chemical resistance, low friction, and compatibility with a wide range of fluids and temperatures.

- Metallic Materials: Metal gaskets may be made of materials such as stainless steel, aluminum, copper, or alloys like Inconel or Monel. Metal gaskets provide high mechanical strength, corrosion resistance, and temperature resistance for demanding applications.

- Composite Materials: Combinations of elastomers, plastics, fibers, and fillers are used to create composite gaskets with enhanced mechanical properties, wear resistance, and sealing performance.

3. Applications:

Infrastructure gaskets find applications in various sectors and industries, including:

- Water and Wastewater Treatment: Sealing flanged connections, pipe joints, manholes, and hatch covers in water and wastewater treatment plants to prevent leakage, odor emissions, and contamination.

- Pipelines and Utilities: Sealing pipe joints, expansion joints, and valve connections in water distribution networks, sewer systems, gas pipelines, and industrial utilities to ensure leak-free operation and prevent fluid loss or environmental pollution.

- Transportation Infrastructure: Sealing expansion joints, bridge bearings, tunnel segments, and rail tracks in transportation infrastructure such as highways, bridges, tunnels, and railways to accommodate movement, vibration, and thermal expansion while maintaining structural integrity.

- Building Construction: Sealing window and door frames, curtain walls, facades, and roofing systems in commercial, residential, and institutional buildings to prevent water infiltration, air leakage, and energy loss.

4. Installation Methods:

Installing infrastructure gaskets typically involves the following steps:

- Surface Preparation: Cleaning and degreasing mating surfaces to ensure proper adhesion and sealing performance.

- Gasket Placement: Placing the gasket onto the mating surface or within the flange groove, ensuring proper alignment and positioning.

- Bolt Tightening: Gradually tightening the bolts or fasteners in a crisscross pattern to evenly compress the gasket and create a uniform seal.

- Verification: Inspecting the assembled joint for proper compression, alignment, and leakage using visual inspection or pressure testing methods.

5. Benefits:

Infrastructure gaskets offer numerous benefits essential for the integrity and functionality of infrastructure systems:

- Leak Prevention: Ensuring leak-tight seals to prevent fluid or gas leakage, environmental contamination, and damage to equipment or structures.

- Corrosion Protection: Providing a barrier against corrosion and erosion in pipe joints, flanged connections, and structural elements exposed to aggressive fluids or environmental conditions.

- Vibration and Noise Reduction: Absorbing vibrations, shocks, and noise generated by machinery, equipment, or transportation systems to minimize structural fatigue and improve comfort.

- Flexibility and Movement Accommodation: Allowing for thermal expansion, contraction, settlement, and movement in infrastructure systems without compromising sealing integrity or structural stability.

- Longevity and Reliability: Offering durable, long-lasting sealing solutions capable of withstanding harsh environmental conditions, temperature fluctuations, and mechanical stresses.

Infrastructure seals are essential components used in a wide range of construction, civil engineering, and industrial applications to provide leak-tight seals, corrosion protection, and structural integrity. With various types, materials, and installation methods available, these gaskets can be tailored to meet the specific requirements of different infrastructure systems, ensuring reliable performance, longevity, and safety. Regular inspection, maintenance, and replacement of gaskets are essential to preserve sealing integrity and prevent system failure or environmental hazards.